QUALITY

The functioning of high-tech products depends on seamless quality control. The complete technological advantages of solder preforms only come to the fore when dimensions, shapes and surfaces are perfectly controlled. At PFARR Stanztechnik we are masters of tight manufacturing tolerances, even with minimal material thicknesses and cut widths.

Our laboratory supports not just research and development; rather it controls every step in the manufacturing process, guaranteeing unwavering product quality to the highest level.

Test procedures

The techniques we use are multi-faceted, reflecting state-of-the-art scientific systems:

| Test procedure | Application | Test details |

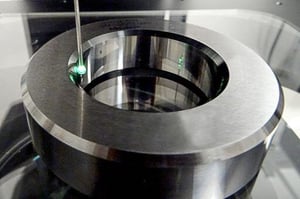

| Dimensional checks | inspecting dimensions against specification | semi and fully automated 2D and 3D CMM measuring systems |

| Flatness measurements | inspecting dimensions against specification | semi and fully automated 2D and 3D CMM measuring systems |

| Hardness testing | inspecting to specification | Vickers hardness testing up to 500 g |

| Surface finish | inspecting to specification | diverse procedures |

| BGA solder sphere inspection and sorting | inspecting to specification | diverse procedures such as size and roundness checks |

| BGA sphere test sort and solder trialing | checking solderability | soldering under vacuum, forming gas or formic acid atmospheres |

| X-ray fluorescence (XRF) | determining the composition of manufactured solders | investigations on samples of Sn, Pb, In, Bi, Ag, Cu and Au based materials | energy and wavelength dispersive systems are available |

| Differential scanning calorimetry | characterising melting and freezing behaviour of the solder | including phase conversion and chemical reactions |

| Preparation and microscopic investigation of polished sections | inspecting and characterising laminates and coating thicknesses | |

| UV and visible spectroscopy | inspection of process auxiliary liquids | |

| Fluorescent spectroscopy | inspection of process auxiliary liquids and firm surfaces | |

| Microscopy | inspection of polished sections (metallography) | Up to 1000 x magnification |

| Determination of surface energy | solder quality inspection | including polar and dispersed fractions |