PRODUCTS

We create your individual products

Whether you require complex stamped preforms in solder or braze, solder spheres, wire products or strips in specific alloy compositions, or perhaps a special variant of one of our many products, PFARR Stanztechnik will offer the maximum possible flexibility in meeting your individual needs. In every product we use only high purity raw materials – delivering quickly, reliably and without complication.

High purity soft solders

Our soft solders are characterised by their excellent solderability. Our general range covers the following solder compositions ( melting points from 115°C – 450 °C).

Typical solder compositions: LIST OF ALLOYS

| Lead-free solders | Lead-bearing solders |

| Sn-based | Pb-based |

| Bi-based | SnPb |

| In-based |

We are pleased to offer individual alloy compositions and alternative alloy systems to meet your specific needs. To obtain a detailed offer please contact our sales department:

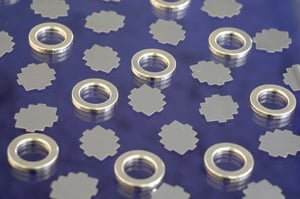

PFDS400®

Under the brand name PFDS400® (Preform-based diffusion soldering technology for high temperature applications: above 400 °C), PFARR Stanztechnik offers a revolutionary multi-layer solder range. Using conventional soldering processes with short dwell maximum peak temperatures of 250 °C, these new composite materials produce complete intermetallic phases (IMPs) in the Lead-free solder junctions without pressure or reheating. The resulting structure exhibits a re-melt temperature of over 400 °C.

The composite materials are made from multi-layer systems of tin-based, lead-free solders, together with high melting point metals such as Copper (Cu). The overall thickness ranges from 50 μm to 300 μm. Other alloys and dimensions are available on request.

We will be pleased to provide a quotation:

SALES

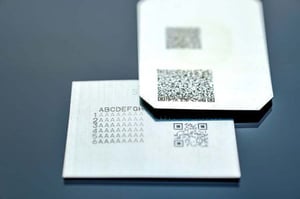

Landal-Seal®

In presenting the patented lead-free solder composition Landal-Seal® PFARR Stanztechnik pushed back the barriers of existing solder technology. The revolutionary composition imparts the material with unusual physical and metallurgical properties: its stability to temperature cycling is around three times higher than that of conventional SnAgCu [SAC] solders, while its special chemical makeup inhibits the formation of Tin whiskers; presenting a much smoother surface finish ideal for positioning BGA solder balls via laser triangulation.

With a eutectic melting point of 214 °C, Landal-Seal® is ideal for a wide range of soldering applications.

We will be pleased to provide a quotation:

SALESHigh purity braze

Our braze materials are alloyed under vacuum, free from oxides, resulting in excellent wettability. The following represent our standard alloy range (from 450 °C melting point).

Typical braze compositions: LIST OF ALLOYS

| Alloy composition |

| Ag-based |

| Cu-based |

| Al-based |

| Au-based |

We are pleased to offer alternative alloy compositions to meet your specific needs. To obtain a detailed offer please contact our sales department:

SALESFlux coating

Flux coating of preforms and solder strip is done to individual customer specification. We coat any geometry or dimensions to agreed customer parameters.

We will be pleased to provide a quotation:

SALES

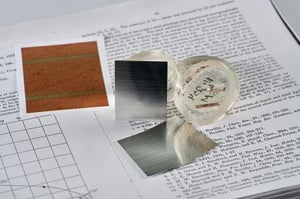

Layered materials

Ever-increasing demands on their geometry and resilience have pushed preforms of monolithic materials towards their limits. Roller laminated materials can provide the answer: sheets of different materials and solders are combined to produce completely different properties.

| Fundamental geometries | |

| Overall thickness | 0,2 mm to 1,0 mm |

| Overall width | ≤ 60 mm strip width |

| Overall width | 0,02 mm to 0,3 mm |

The classic system consists of a Copper or Nickel carrier, coated both sides with an alternative material cladding. Single-sided and asymmetrical cladding is, however, also feasible.

Alternative geometries, different cladding, other thicknesses and strip widths, out-sourced plating, etc. are all available for individual discussion. We will be pleased to provide a quotation:

Plastic stamping

Precision stampings in plastics are an important part of our product portfolio. We can work with any polymer material exactly to your wishes. We already punch an enormous range of plastics.

We will be pleased to provide a quotation:

SALESTargets

Thin, precious metal coatings in ultra-high purity can be applied to numerous substrates using vapour deposition. The process requires high-purity targets available from Pfarr Stanztechnik. Vapour deposition is used in many electronic products, in optics and medical technology as well as in measurement and control technology; whether onto glass, mirrors or solar cells.

Our exacting process monitoring guarantees an homogenous material quality and unvarying metal structure. We also offer non bonded sputter targets to customer specification.

We will be pleased to provide a quotation:

| Target options | |

| Precious metal target materials | Ag, Au, Pd, … |

| Base metal target materials | Al, … |

| Target purity | 3N5 – 5N |

| Target design | to customer specification |